Table of Contents

ToggleBest Pump Spray Gun for Garden Fruits – Easy Spraying for Healthy Plants

R.K. AGRO INDUSTRIE Pvt. Ltd., commonly known as R.K. AGRO, is a well-established name in the agricultural equipment industry. The company was founded in 2006 with a vision to revolutionize the agricultural sector by providing farmers with high-quality, innovative, and efficient spraying and dusting solutions.

Humble Beginnings

Like many successful businesses, R.K. AGRO had a modest start. The company’s first product was a Hand Rotary Duster, a manually operated agricultural tool used for dusting crops with pesticides and fertilizers. This simple yet effective product laid the foundation for what would become a rapidly growing company.

Growth Through Innovation and Research

From its early days, R.K. AGRO recognized the importance of innovation and research in agriculture. The company invested heavily in developing new technologies tailored specifically for the Indian agricultural landscape. Given India’s diverse farming practices, varying crop types, and climatic conditions, R.K. AGRO focused on designing equipment that could cater to the unique needs of Indian farmers.

By consistently improving its products and introducing advanced agricultural machinery, the company quickly gained a reputation for reliability and efficiency. This helped R.K. AGRO expand its product range and establish itself as a market leader in the agricultural sprayer and duster industry.

Market Leadership

With its dedication to quality, efficiency, and customer satisfaction, R.K. AGRO became one of the leading manufacturers of agricultural sprayers and dusters. Farmers across India came to rely on the company’s equipment for enhancing productivity and protecting their crops from pests and diseases.

Diverse Range of Products

R.K. AGRO offers a wide variety of agricultural sprayers and dusters, each designed for specific farming needs:

Hydraulic Power Sprayers

These are high-pressure sprayers powered by an engine or motor.

Used for spraying pesticides, herbicides, and fertilizers over large fields.

Suitable for crops like cotton, vegetables, fruits, and tea plantations.

Ensures uniform spraying, improving pest control efficiency.

Tractamount Sprayers (Tractor Trailed Sprayers)

These are heavy-duty sprayers attached to tractors.

Ideal for large-scale farming operations.

Covers extensive farmland with ease, reducing manual labor and operational time.

Foot & Rocker Sprayers

Operated by foot or hand motion to build pressure.

Commonly used by small and medium-scale farmers.

Affordable and easy to use, making them a cost-effective choice.

Hand Compression Sprayers

Small, manually operated sprayers used for targeted spraying.

Best for nurseries, small farms, and home gardening.

Commonly used for pesticides and fungicides on vegetable crops and flowers.

Continuous Knapsack Type Sprayers

Worn on the back like a backpack, allowing continuous spraying.

Popular among farmers who need to move around while spraying.

Used for crops like wheat, rice, pulses, and vegetables.

Small Hand Sprayers

Compact sprayers for home gardens and small agricultural plots.

Best for precision spraying on flowers, herbs, and ornamental plants.

Conclusion

Through its commitment to innovation, quality, and efficiency, R.K. AGRO INDUSTRIE Pvt. Ltd. has grown from a small manufacturing unit into a leading name in the agricultural equipment sector. By continuously upgrading its products and catering to the specific needs of Indian farmers, the company plays a significant role in boosting agricultural productivity and supporting sustainable farming practices.

BRUSH CUTTER BLOG'S

Brush Cutter

BRUSH CUTTING EQUIPMENT uses single or multiple blades to cut a grass surface up to a uniform height. Here, the height of the grass you should cut remains fixed. However, operators may adjust the grass-cutting device by using a single master lever or by the combination of a nut and bolt on each machine wheel. Regardless of the adjustment feature, a grass cutter trims the lawn grass more easily than other equipment in the agricultural industry. Here, you will know a few benefits and types of grass cutting equipment.

Types of Grass Cutting Machines

Manual Grass Cutters

Manual Brush Cutter cut the grass similar to scissors. They do not chop or tear the grass. These devices are available with a spinning blade at the top of a conventional rotary mower to chop off the grass. The machines work well on well-maintained yards.

Electric Brush Cutter

Many people like self-propelled and electric cordless Brush Cutter These machines are more convenient than their manual counterparts. Besides, cordless mowers can maneuver easily and do not need petrol, oil changes, air filters, or spark plugs.

How Grass Cutting Machines Benefit You

As a piece of essential farm machineri and eqiepment, grass cutters possess the following features to benefit lawn owners.

Versatility

Brush cutters have compatibility with many blade attachments so that you may use the tool on diverse materials. You need a single device to accomplish landscaping tasks rather than purchasing different agricultural tools.

Durability

Brush cutter of heavy-duty metals. Hence, they may last for a long time if you maintain them properly. In many cases, you can use the same one for many years. Only, you have to replace or sharpen the blade periodically before using the device on thick branches and power equipment. Working with a blunt blade not only reduces the lifespan of your tool but also leads to many safety hazards.

Power

The design of the Brush cutting machine allows it to power through various woody areas. It works well in those areas where an overgrown brush, a conventional line trimmer, or lawnmower cannot work. The blades are available in many variations to work well in tight areas, where you cannot use any large equipment.

Comfort

Operating power equipment for many hours may sometimes become cumbersome. It also put you at a risk related of a severe accident. Many designers design their grass-cutting devices by considering the requirements of their users. Hence, they always include certain features, like anti-vibration technology, and a straight shaft to avoid discomfort at the time of work. The application of a harness will let you control the tool easily. Simultaneously, you may reduce the strain level on your back and arms.

Therefore, with so many features, Brush-cutting machines can ease trimming grass lawns.

Source

Agriculture Sprayers and Dusters by R.K. Group Of Companies, india www.rkagroindustrie.com

Resource Box

R.K. Agro Industries Pvt. Ltd. popularly known as R.K, a pioneer in the field of agricultural equipment, was established in 2006.

Chain saw

CHAIN SAW

A chainsaw consists of the powerhead, bar, and chain. The powerhead has two integrated handles for handling the saw.

The bar is a made of flat steel with grooves cut in the edges within which the chain runs. They may have a sprocket mounted in the tip or a solid tip. A sprocket increases the efficiency and decreases wear on the bar and chain. The diameter of the bar tip affects the possibility of kickback. Kickback is a condition where the chain catches on the material and forces the tip of the bar up, rotating the chainsaw around the handle. This dangerous condition can seriously injure the operator. A smaller tip diameter decreases the likelihood of kickback.

All modern chainsaws have a chain brake capable of stopping the chain instantaneously in the event of kickback. The brake is actuated by a bar that runs across the front of the top handle of the chainsaw. When the saw rotates back toward the operator, it forces the chain brake bar against the arm of the operator, actuating the chain brake and disengaging the chain before the chain can strike the operator.

Chains come in a variety of pitches, the distance between three rivets in the chain, gauges, the width of the drive link, and cutter teeth. Some chains are referred to as safety chain and contain special links and design features that decrease the likelihood of kickback.

Some chainsaws are sold for cold weather applications and include warmers built into the handles for operator comfort and safety.

Physical Limitations

Chainsaws come in a range of power sizes that correspond to available bar lengths. The length of the bar determines the size of material that can be effectively cut. Material larger in diameter than the length of the bar can be cut, but doing so affects productivity and safety to the operator. The larger, heavier saws may fatigue the operator and affect safety. It is important to size the chainsaw properly for the material being cut. Some operators prefer a longer bar than is necessary to cut through material when delimbing or bucking logs lying on the ground to minimize the amount of operator bending.

Chainsaw felling is generally not limited by slope or soil conditions. In cases where either condition prevents chainsaw felling, there is often no other alternative to accessing the site for treatment.

Treatment Options

Chainsaw felling and processing is generally considered feasible for any type of treatment. Its major disadvantage is the decreased productivity compared to mechanical options. This decreased productivity may translate into increased treatment costs.

Safety Concerns

The inherent dangers of working unprotected, other than by a helmet and chaps, are the main concerns with chainsaw operations. Areas susceptible to windthrow, due to shallow rooting or numerous snags, and burned areas tend to present greater danger to the operator.

Steep slopes with uneven or unstable ground also present hazards to chainsaw operators.

Chainsaws produce high frequency vibrations that are capable of fatiguing the operator. Most chainsaws contain vibration-mitigating measures to decrease the affects of vibration.

Two stroke gasoline engines power most chainsaws used in the woods. These engines operate at high RPMs and produce loud noises. Operators should always wear hearing protection while operating chainsaws.

Chainsaw operators are in danger from falling objects and fatigue. Fatigue can be caused by the vibration and noise produced by the chainsaw as well as constantly walking and working in rough terrain. Falling objects include not only the tree itself, but also limbs and small trees knocked down by the falling tree. Operating in windy conditions increases this danger to the operator.

.

System Interactions

Because chainsaw felling and processing leaves material scattered through the stand, it is generally not used in conjunction with grapple skidders or forwarders. Other than those extraction methods, it works well with animals, cable skidders, cable, and helicopter extraction.

The number of chainsaw operators should be matched to the productivity of the extraction method to avoid slowing the productivity of that stage in the process. High productivity extraction like helicopters will require a greater number of fallers working days in advance of the extraction process. For lower productivity extraction like animals or grapple skidders, the number of fallers can be decreased and may be able to work within the same unit that extraction is taking place.

Research

The following is a selection of representative research studies and reports done on harvest systems that include chainsaw felling. These reports may be used to get an idea of productivity and impacts of different systems and uses of chainsaw felling as well as some of their limitations. When reading these reports, keep in mind that they describe specific systems and stand treatments. Trying to apply the lessons learned from these reports to systems and treatments outside of the studies’ scope may have unintended or unforeseen consequences.

This is not a complete listing of research on chainsaw felling. Additional information can be found at the U.S. Forest Service Treesearch website. This site provides reports for research performed by Forest Service Research and Development scientists and their collaborators.

CAR WASHING GUN

High Pressure Car Washing Nozzle – Ultimate Guide by RK Agro

When it comes to vehicle maintenance, one thing every owner agrees on is the importance of keeping their car clean and shining. A neat and well-maintained car not only looks attractive but also ensures long-term protection of the paint, metal body, and overall performance. Washing your car at home can often be tiring and time-consuming, especially if you rely on traditional methods like buckets and cloth. That’s where a High-Pressure Car Washing Nozzle from RK Agro comes in as the perfect solution.

In this blog, we will dive deep into the features, benefits, uses, and buying guide for a high-pressure car washing nozzle, and why RK Agro is the trusted name to provide you with the best cleaning tools.

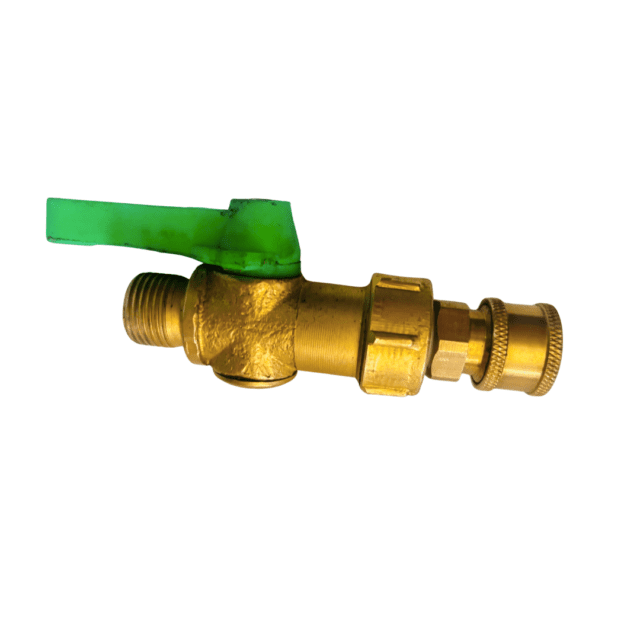

🚗 What is a High-Pressure Car Washing Nozzle?

A high-pressure car washing nozzle is a specially designed attachment that connects to a water hose or pipe. Its main function is to increase water pressure and allow users to control the flow according to the cleaning requirement. Unlike regular pipes, these nozzles can shoot out water in powerful jet streams, making it easy to wash away mud, dust, oil stains, and sticky dirt from cars, bikes, and other surfaces.

Whether you are a car owner, bike enthusiast, or someone who likes to keep their property neat and clean, this tool is a game-changer for effective cleaning.

🌟 Key Features of RK Agro High-Pressure Car Washing Nozzle

At RK Agro, we focus on quality, durability, and efficiency. Our high-pressure nozzles are built to perform and last. Here are the main features that make them stand out:

Adjustable Spray Modes – Switch easily between mist spray for delicate surfaces and jet spray for heavy dirt.

High Pressure Output – Delivers a powerful water stream that removes even stubborn mud and grease.

Sturdy Build Quality – Made with premium-grade materials to prevent rust, cracks, and damage.

Easy Grip Handle – Comfortable to hold for longer washing sessions.

Universal Compatibility – Can be attached to most garden hoses, water pipes, or car washing pumps.

Portable & Lightweight – Easy to carry, store, and use anytime, anywhere.

💡 Why Every Car Owner Needs a High-Pressure Washing Nozzle

Owning a car comes with the responsibility of maintaining its shine and performance. Many people spend money regularly at car wash centers, but with a high-pressure nozzle, you can do it at home without hassle. Here’s why it’s a must-have:

Time-Saving – Wash your entire car in just 10–15 minutes.

Cost-Effective – Say goodbye to expensive car wash bills.

Eco-Friendly – Consumes less water compared to buckets or open pipe washing.

Better Cleaning – High pressure ensures dirt is removed from small gaps, wheels, and corners.

Paint-Friendly – Adjustable spray protects car paint from scratches.

Multi-Purpose Use – Can also be used for cleaning bikes, floors, windows, gardens, and outdoor furniture.

🛠️ How to Use RK Agro Car Washing Nozzle

Using a high-pressure nozzle is simple, even if you are new to DIY car washing. Here’s a step-by-step guide:

Attach the Nozzle – Connect the nozzle to your water hose or pipe. Ensure it is tightly fitted to avoid leakage.

Adjust the Spray Mode – Choose jet mode for tires, mudguards, and underbody, and mist mode for glass and paint.

Start Washing – Rinse the car with water before applying shampoo or soap.

Apply Car Shampoo – Use a sponge or foam sprayer to apply soap.

Rinse with High Pressure – Remove all soap and dirt with a strong water jet.

Dry the Car – Use a microfiber cloth to wipe and prevent water spots.

🌿 Environmental Benefits

Many people don’t realize that traditional bucket or open-pipe washing wastes hundreds of liters of water. A high-pressure nozzle helps reduce water consumption by up to 50%, making it an eco-friendly choice. At RK Agro, we strongly believe in promoting sustainable products that protect both your car and the environment.

📊 Comparison: High-Pressure Nozzle vs. Regular Washing

| Feature | High-Pressure Nozzle | Regular Pipe/Bucket |

|---|---|---|

| Cleaning Speed | Fast (10–15 mins) | Slow (30–40 mins) |

| Water Consumption | Low | High |

| Dirt Removal Efficiency | Very Effective | Limited |

| Paint Protection | Safe (adjustable) | Risk of scratches |

| Cost Savings | High (one-time buy) | Low (repeated car wash costs) |

Clearly, investing in a high-pressure nozzle is a smarter and more cost-effective decision.

🔧 Maintenance Tips for Long Life

To make sure your RK Agro high-pressure nozzle lasts long, follow these tips:

Always clean the nozzle after use to avoid clogging.

Store it in a dry place to prevent rust.

Avoid dropping or hitting it on hard surfaces.

Use compatible hoses and avoid high-pressure pumps beyond recommended levels.

🛒 Why Buy from RK Agro?

At RK Agro, we are committed to delivering quality, trust, and customer satisfaction. Our high-pressure car washing nozzles are:

Tested for durability and performance.

Affordable compared to market alternatives.

Backed by customer support and guidance.

Suitable for both home users and professional cleaners.

We also provide a range of agricultural and industrial tools, ensuring that every product from RK Agro meets your expectations of strength, reliability, and value for money.

✅ Conclusion

A clean car is a happy car, and with the RK Agro High-Pressure Car Washing Nozzle, you can achieve professional-level cleaning at home. It saves time, money, and water while giving your car the shine it deserves.

So, if you are tired of spending hours washing your car or paying heavy bills at car wash centers, it’s time to switch to a smarter solution.

👉 Order your RK Agro High-Pressure Car Washing Nozzle today and experience effortless cleaning like never before!

TUNGSTEN CARBIDE ( JAPAN BLADE )

Tungsten Carbide Tipped Brush Cutter Blade – 255mm, 40T Black (Made in Japan)

Experience superior cutting performance with the Tungsten Carbide Tipped Brush Cutter Blade, designed for heavy-duty and precision cutting applications. Measuring 255mm in diameter with 40 ultra-sharp teeth, this blade is crafted for durability, efficiency, and smooth operation.

Manufactured with premium tungsten carbide tips, it delivers exceptional sharpness and long-lasting performance, making it ideal for cutting thick grass, weeds, small trees, and dense brush. The 25.4mm arbor hole ensures perfect compatibility with most standard brush cutters and trimmers.

Built with Japanese precision engineering, this blade guarantees high-speed, clean cuts and reduced vibration for operator comfort. Its heat-treated alloy body ensures stability and resistance against wear, even under demanding conditions.

Key Features:

-

Size: 255mm (10 inches) diameter

-

Teeth: 40T Black Tungsten Carbide tipped teeth

-

Arbor Hole: 25.4mm (1 inch)

-

Material: High-grade steel with carbide tips

-

Origin: Made in Japan

-

Usage: Suitable for brush cutters, grass trimmers, and clearing saws

-

Performance: High cutting efficiency, longer blade life, and smooth operation

Applications:

Perfect for cutting:

-

Thick grass and weeds

-

Shrubs and light bushes

-

Bamboo and small branches

-

Agricultural and landscaping maintenance